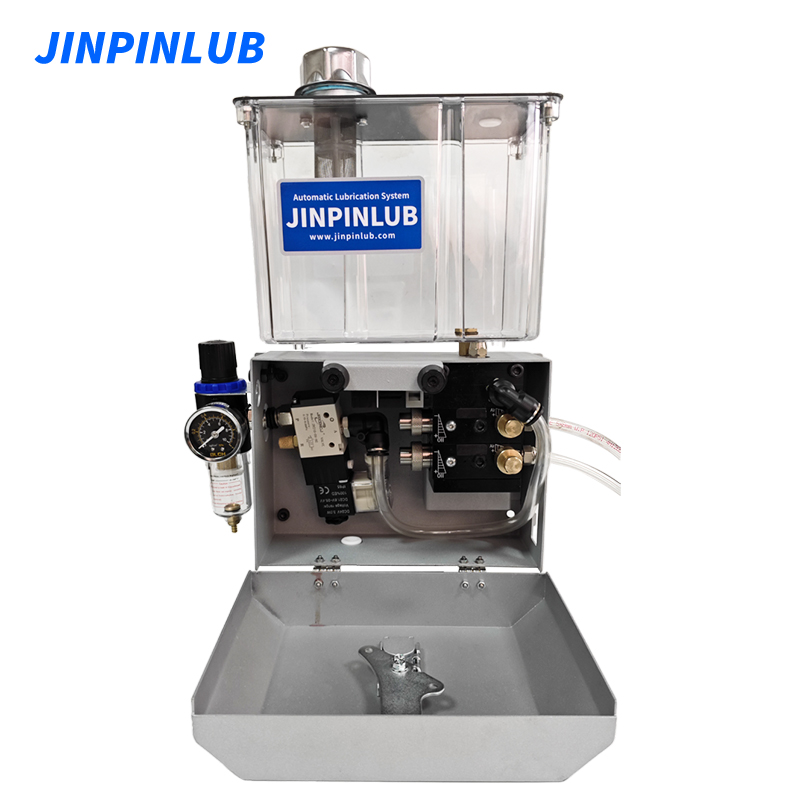

Micro Precision Spray Lubrication System For Metal Cutting

MLS micro-lubrication pump is a device used to replace the traditional water-soluble cutting fluid cooling system. It sprays a mixture of air and oil into the processing area through high-pressure atomization, so that a small amount of lubricating oil is more evenly dispersed.

Описание

Особенность

– Air and oil mixture: minimum quantity lubrication pump can provide a mixture of air and oil that may be used for different application scenarios requiring precise lubrication.

– Adjustment function: Stroke regulator and pulse generator in minimum quantity lubrication pump allow users to regulate the circulation rate and output per stroke of the pump according to requirement, hence accurate regulation.

– Environmentally friendly: The ISO VG 68 machine tool guide oil recommended by the pump has environmentally friendly characteristics, and precise micro-oil mist lubrication can further reduce the impact on the environment.

– High-performance materials: Nozzles of different materials are suitable for different working environments, such as stainless steel nozzles for environments that require high rigidity, while flexible plastic nozzles are suitable for environments that require easy adjustment of direction.

Спецификация

| Supply air pressure | Clean, dry compressed air, 4~7 bar, 708 LPM minimum |

| Pump viscosity | 50~1000 SUS |

| Pump output at full stroke | 0.033mL (1-drop standard), 0.100mL (3-drop standard) |

| Pump output rate | 0~396mL/hr (1-drop standard), 0~1200mL/hr (3-drop standard) |

| Air flow rate | 0~4 SCFM for each air and oil output, 1~2 SCFM typical |

| Pulse generator | 5~50 pulses/min, Max 200pulses/min(not recommended) |

| Рабочая температура | 0℃ ~ +50˚C |

| Storage temperature | (-16℃ ~ +70˚C) |

| Fluid reservoir | Customizable, standard 0.5L, 1.0L, 2L, 4L |

Монтаж

1. Installation preparation: Read the operational manual, understand the principles of the minimal quantity lubrication system, component functions, and adjustment methods. Prepare all the tools which may be required for mounting.

2. Installation location: Choose a place close to the machine and easy for operation and maintenance, making sure the minimal quantity lubrication pump is installed horizontally with the liquid storage tank up.

3. Installation method: Fixed by screws at four installation places minimum quantity lubrication system. As for the case magnet installation method is adopted, it needs to be installed in clean and flat installment location.

4. Air connection: Keep the air supply pressure between 4 -7 bar, connect the air supply line through the air filter, and seal the interface.

5. Thin oil filling: Fill in the qualified thin oil to 75% of the volume of the oil tank. In the process of filling, push down the cover to discharge extra air.