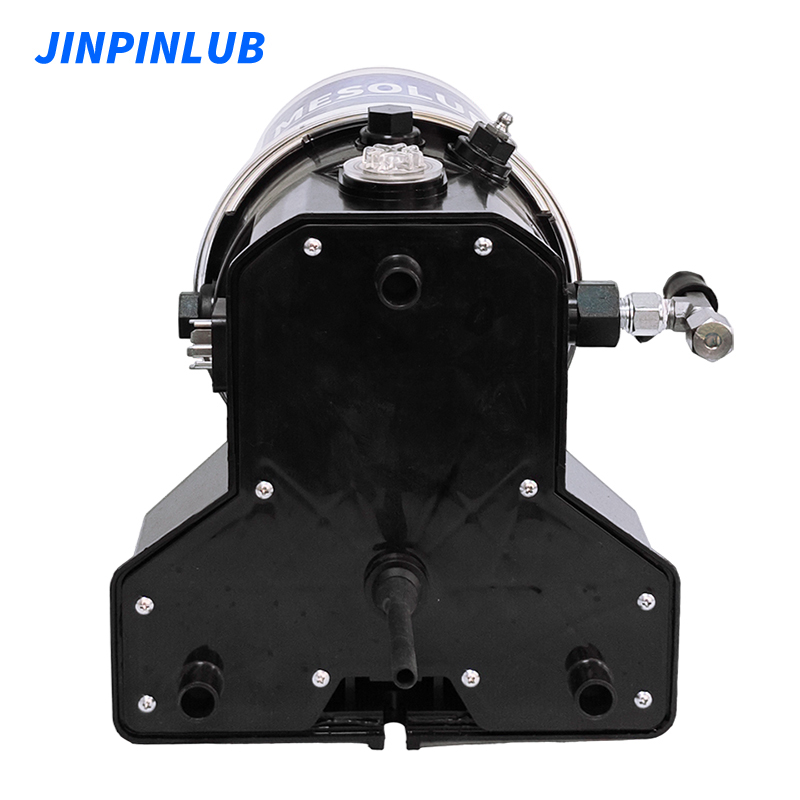

J203 Automatic Lube System Equipment For Off-Road Equipment

The PCB panel of the J203 lubrication pump realizes the automatic control of the centralized lubrication system. It can adjust the lubrication cycle and flow rate according to the actual needs of the equipment to ensure that the equipment is properly lubricated.

Description

Features

Main functions of the PCB:

Automatic control: Automatically control the operation of the lubrication pump according to the preset program, including the start, stop and lubrication cycle of the electric lubrication pump.

Lubrication process monitoring: Monitor the lubrication flow and system pressure to ensure the normal operation of the lubrication system.

Fault alarm: When a lubrication system fault is detected, such as low oil level or lubrication pump failure, lubrication will be automatically stopped and an alarm will be issued.

Precise lubrication: The PCB panel ensures that the lubricant is accurately delivered to the lubrication point when needed by controlling the operation of the lubrication pump, avoiding over-lubrication or under-lubrication. At the same time, real-time monitoring of the status of the lubrication system can identify problems before failures occur.

Specification

| Operating temperature | (-40°C to +70°C) |

| Number of outlets | 1, 2 or 3 |

| Reservoir capacity | 2L, 4L, 8L |

| Refilling | Hydraulic lubrication fitting or from top |

| Lubricant | Greases of at least NLGI grade 2, Oils up to 40mm²/s (cSt) at 40° C |

| Class of protection | IP6K 9K |

| Piston diameter, K5 | 5 mm, approx. 2 cm³/min |

| Piston diameter, (standard) K6 | 6 mm, approx. 2.8cm³/min |

| Piston diameter, K7 | 7 mm, approx. 4 cm³/min |

| Max. operating pressure | 350 bar |

| Connection thread | G 1/4 |

| Operating voltage | 12VDC, 24VDC, 110-240 VAC |

Application

Determine if the lubrication pump should be replaced.

Degraded Performance: It is when the discharge of the lubrication pump goes down or the discharge pressure goes down; it can result from the wear or aging of internal parts of the pump.

Abnormal noise: In the operation of a lubrication pump, if it produces abnormal noises, such as humming or creaking, then this may be a manifestation of its internal parts being damaged or loose.

Pump leakage: If lubricant seeps from the body or pipe interface of a lubrication pump, it can be due to either a damaged or aged seal.

Service life: Following the user manual of the lubrication pump, the lubrication pump shall be replaced if it has reached its recommended service life.