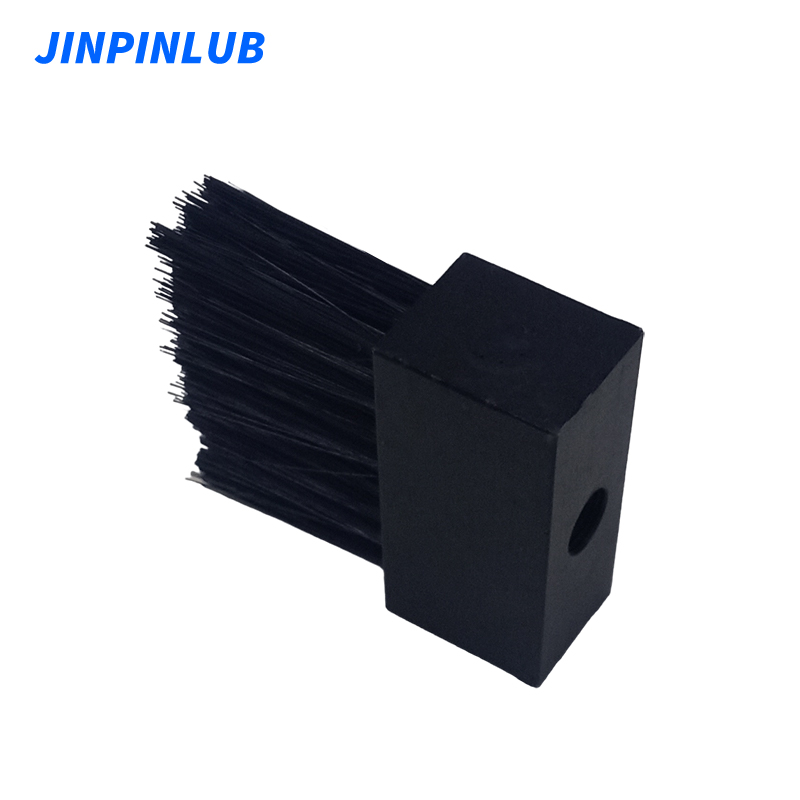

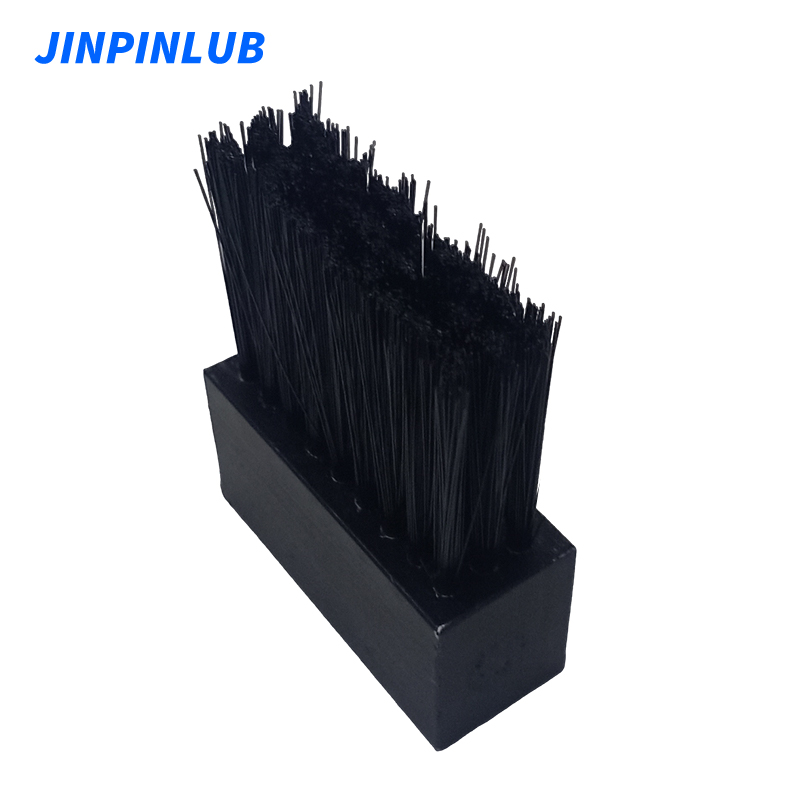

Brosse à huile en nylon avec base pour la lubrification du rail de guidage de la chaîne

Nylon oil brushes are used in automatic lubrication systems, for chain lubrication, guide rail lubrication, etc. They can not only provide sufficient infiltration lubrication to the lubrication parts, but also remove impurities such as dust and debris stuck to the lubrication parts.

Description

Caractéristiques

In order to solve the shortcomings of manual lubrication of the chain, we recommend the use of timed automatic lubrication, combined with oil brushes for good lubrication.

1. Extend the service life of the chain.

2. Reduce the number of downtimes and downtime.

3. Reduce energy loss.

4. The oil brush can reduce the loss of lubricating oil.

5. The oil brush can absorb the vibration and impact of the chain and reduce noise.

6. Reduce the temperature of the high-speed running chain.

7. The oil brush removes dust and impurities, etc., and better forms an oil film to protect the transmission of the chain.

The optional common sizes of chain brushes are 30mm, 45mm, 60mm, and 80mm.

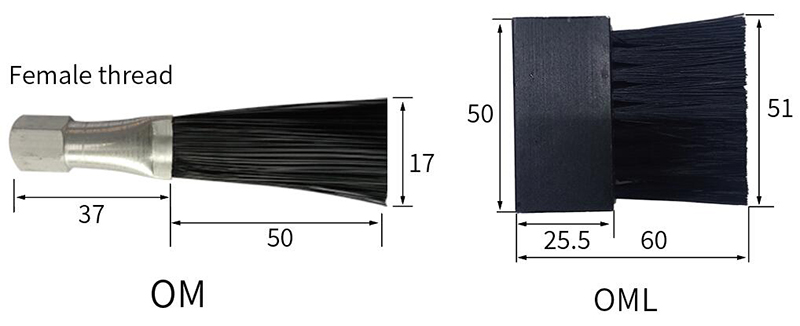

Spécification

| Modèle | Female thread | N.W. (g) |

| OM408 | M8xP1.0 | 11 |

| OM610 | M10xP1.0 | 15 |

| OM601 | PT1/8 | 17 |

| OML601 | PT1/8 | 25 |

| OML401 | PT1/8 | 27 |

Application

The most widely used application of automatic lubrication system brushes is chain lubrication. It mainly includes conveyor chains, transmission chains, special professional chains, pull chains, etc. Chain transmission is widely used in the field of mechanical transmission. Most traditional chains use high-viscosity lubricating oil and grease, which are manually applied to the surface of the chain. The chain automatic lubrication system with oil brushes can solve most chain failures, such as:

When the inside of the chain is not fully lubricated, it is easy to cause wear and corrosion, causing the chain to loosen or kink.

When the chain is running, the high speed will throw off the lubricating oil attached to the surface, causing the chain to lose the protection of the lubricating oil.

When the chain is running, the environment is humid or dusty, then dust and other impurities are likely to enter the inside of the chain and cause wear and corrosion.