Company Profile

We are a professional enterprise engaged in the research and development, production, and sales of centralized lubrication systems. Our products are renowned for their high stability, sturdy reliability, excellent sealing performance, and high output pressure. The company operates on the principles of integrity, quality, and continuous innovation, committed to providing customers with low-cost and high-quality ideal solutions. From product design and accessory selection to product assembly, finished product testing, and sales services, we always ensure the provision of various centralized lubrication systems.

Main Products

According to customer needs, we provide various automatic centralized lubrication pump systems. For example, electric motor oil lubrication system, electric grease lubrication system, pneumatic micro lubrication system, pneumatic oil mist lubrication system, single point lubrication system, grease dual line lubrication system. Lubrication pumps are widely used in machine tools, automation, construction machinery, agricultural and forestry equipment, mining and cement industries, food and beverage, steel industries, pulp and paper industries, and wind energy.

Technical Team

Our technical team is composed of a group of experienced and skilled engineers, including mechanical design engineers, hydraulic control engineers, material engineers, etc. They have the ability to independently develop new products and new processes. In the past few years, the team has obtained a number of utility model patents in lubrication systems, such as oil-gas lubrication devices, electric dual-mode lubrication pumps, sensor-type distributors, micro-oil-gas oiling machines, oil-gas cooling systems, integrated lubrication pumps, electric grease lubrication pumps, new sprayers, etc.

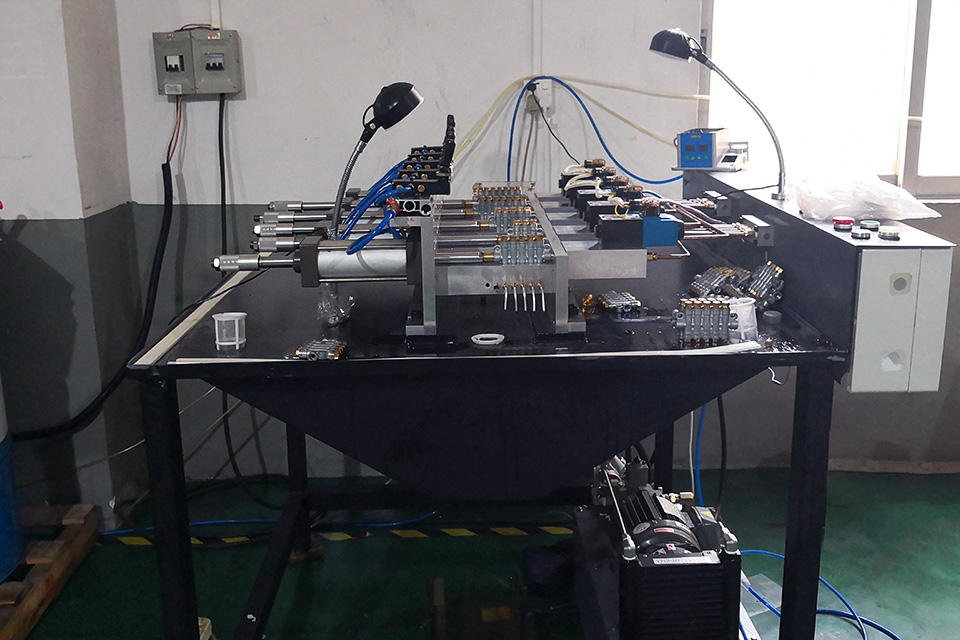

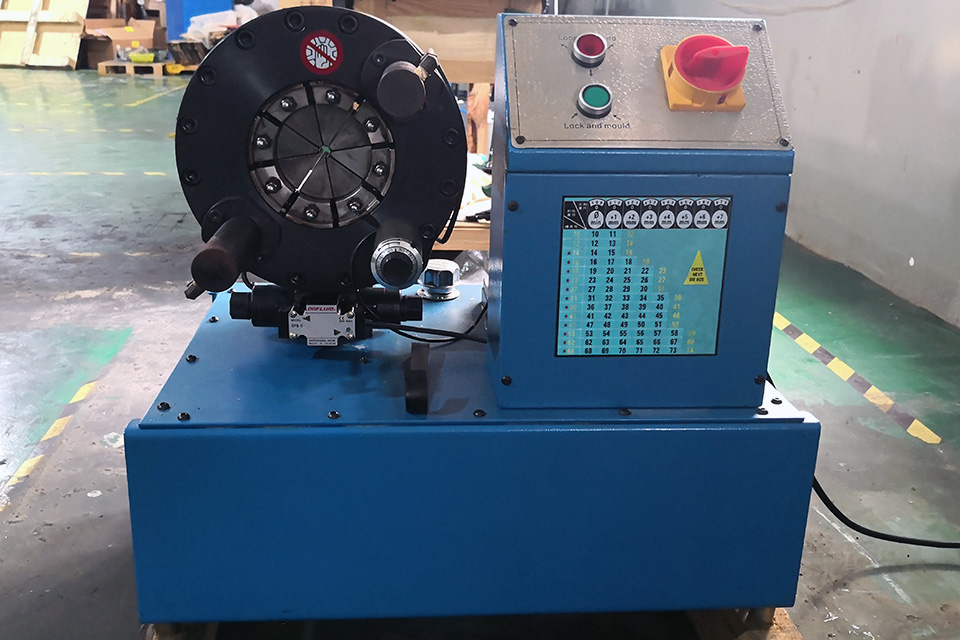

Manufacturing

Our products are supported by a processing factory with strong productivity. The factory has complete processing equipment, including CNC lathes, automatic drilling machines, sheet metal processing equipment and other types, which are efficient, accurate and intelligent. These equipment can meet the processing needs of different types of materials, achieve high-precision and high-efficiency production, provide the company with strong processing capabilities, and help the company maintain its leading position in market competition.

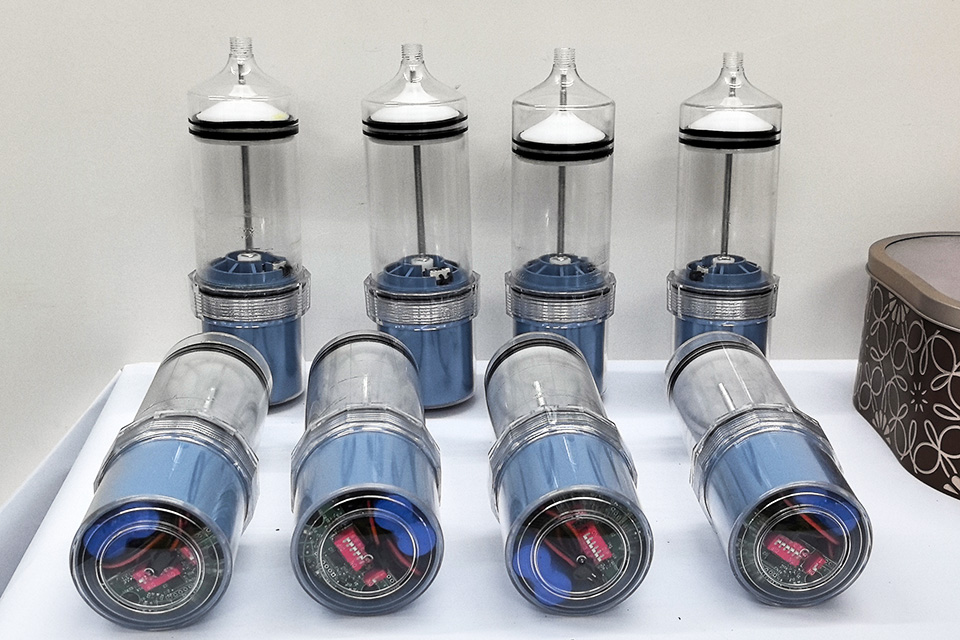

Quality Control

In addition to strict production process control, our lubrication system also undergoes strict product quality control before delivery. The testing equipment includes high and low temperature testing machines, salt spray testing machines, aging testing machines, vibration testing machines, air pressure sealing testing machines, lubricant flow testing machines, low liquid level sensor testing, and overflow valves, reversing valves and other valve tests. These lubrication pump test equipment together constitute a complete test system to ensure the performance, reliability and durability of the lubrication pump.

Business Partners

Jinpinlub lubrication pumps have a wide range of main application areas, covering multiple key industries. Machine tool field, railway locomotive, iron and steel metallurgy, mining field, automobile manufacturing, printing machinery, packaging and processing machinery, food and beverage machinery and textile machinery and other fields. In the past few years, our team has served more than 1,000 companies around the world, mainly in Europe and South America. Our lubrication systems are known for cost-effectiveness, high efficiency and energy saving, which can improve the competitiveness of customers’ products while saving costs.