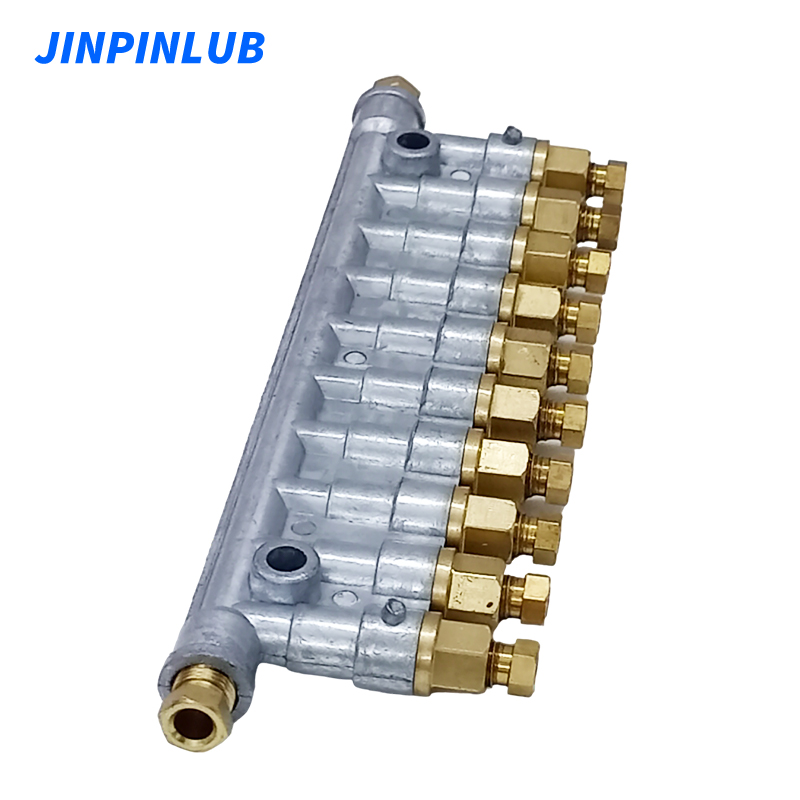

DPB1 High Quality Pressurized Oil Distributor For Volume Pump

DPB1 pressurized distributor is a device used in volumetric lubrication systems, mainly used to accurately control the distribution of lubricating oil. It usually adopts a spring piston structure to achieve oil storage and discharge through system pressurization and depressurization.

Description

Features

1. Accurate discharge, can be selected based on lubrication point requirements.

2. It is used with a volumetric pump to discharge lubricant when pump output pressure reaches distributor pressure.

3. The standard style is sleeve type, with sleeve type connectors.

4. It is recommended to use the quick insertion connector with a nylon tube.

Specification

| Function principle | Pressurized Distributor |

| Outlets | 2, 3, 4, 5, 6, 8 ,10 |

| Metering quantityoil | 0.03, 0.06, 0.10, 0.16mL/cycle |

| Lubricant | 32~90 cSt@40°C (Oil), ≤NLGI 0 (Grease) |

| Operating temperature | 0 to +80 °C |

| Operating pressure | 8~30bar(Oil), 20~50bar(Grease) |

| Material | Zinc die-cast, brass |

| Connection outlet | Inlet Φ6(M10x1), Outlet Φ4(M8x1) |

| Outlet fittings | Sleeve type, Quick type |

| Mounting position | Any |

Principle

1. The pumped oil pushes up the umbrella valve in the distributor.

2. After the umbrella valve closes the center hole of core rod, oil pressure forces the piston to rise against the spring force

and discharge oil originally stored in upper chamber.

3. When the piston moves to the top of the oil chamber, the oil discharge is completed.

4. When the pump stops supplying oil, the pressure relief valve is activated, the system pressure drops, and the piston

returns under the spring force. When the umbrella valve closes the oil inlet, piston presses the oil in the lower chamber to

the upper chamber through the small hole of the core rod, and oil storage for next cycle is completed.